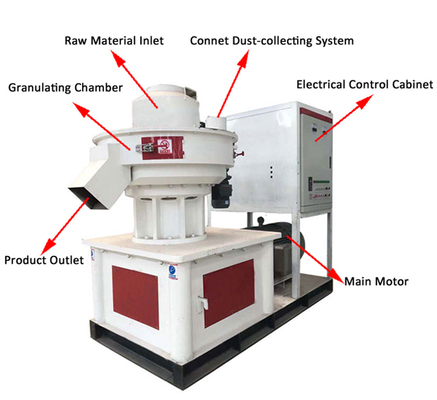

Wood machine pellet is a kind of molding equipment which can compresses agricultural and forestry biomass(disperse finely divided,non-shaped)into a rod-shaped and granular shape under the action of a certain temperature and pressure.Biomass granules can use biomass and other wastes such as wood chips, straw, rice husks and bark as raw materials, and solidify them into high-density granule fuels through pretreatment and processing. It is an ideal fuel to replace kerosene. It can not only save energy but also reduce soot emissions, but also economic and social benefits. It is an efficient and clean renewable energy source.

Deixe um recado

Ligaremos para você em breve!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Submeter

Mais informações facilitam uma melhor comunicação.

Senhor

- Senhor

- Senhora

Está bem

Submetido com sucesso!

Ligaremos para você em breve!

Está bem

Deixe um recado

Ligaremos para você em breve!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Submeter